Supply chain resilience over the past 3 years has been the subject of many column inches, but what does this mean to companies on an operational level?

Overview

Supply chain resilience addresses (or should at least) some of the disruption to global markets that has been seen these past years. With more frequent supply chain shocks, which are of increasing severity, the ability for companies to mitigate these risks will be important given the adverse economic headwinds that are building in Western markets.

Supply chains that reach across continents and Oceans are already complex. Overlay these with the disruption and inflationary factors that are now evident the world over, and it just got a lot more complex. But for ‘Product companies’ (retailers, wholesalers, distributors etc), the supply chain is an integral function of the business. Without the suppliers, there are no products. And without products there is no business.

A Strategic Function

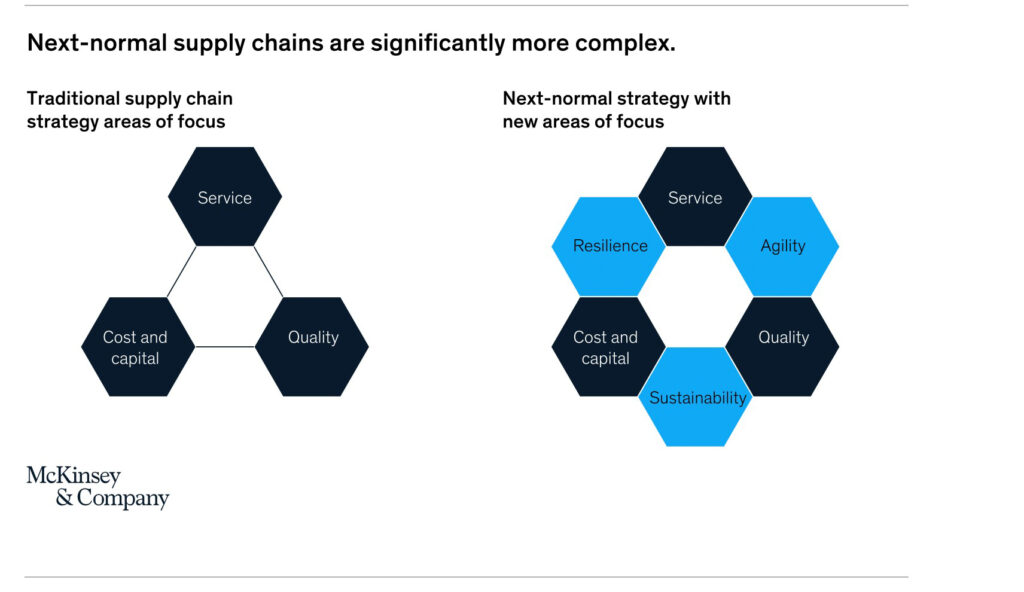

Consequently, CEOs across the globe are increasingly focusing their attention on their supply chains and their impact and implications. Sourcing is being recognised as a critical function in the delivery of business strategy. Whereas the traditional focus was on Price, Quality & Service, this triumvirate has now been also coupled with Resilience, Agility & Sustainability.

These new challenges are forcing an intense focus on supply chain priorities and team structures and responsibilities. This encompasses both the relevant expertise and knowledge to leverage one’s sourcing capability as well as the necessary market coverage.

Future Proofing:

The business need to navigate a robust and resilient pathway through these dynamic events are focusing attention on the any sourcing function. Supply chain resilience ultimately means building capability for a plan B and plan C, and maybe even plan D. But unlike the past where most supplier matrices focused solely on the China market, these options will likely straddle multiple markets, which further overlays complexity.

Whilst the need to ensure quality product that is delivered in good time remains the same. The traditional (sometimes obsessional) focus on price is now having to be balanced with the need for resilience and visibility of supply (i.e. some products are better than none!).

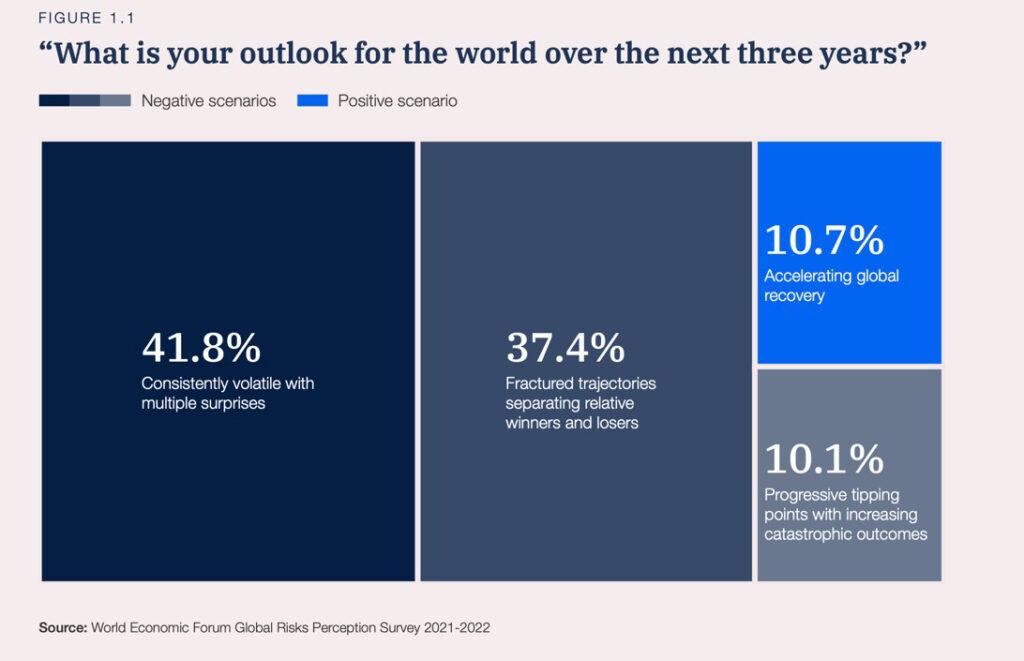

McKinsey in their recent report on supply chain resilience, describe a scenario where supply chain management becomes increasingly complex in the near future to respond to new and divergent demands. As the World economic Forum risk register suggests, the likelihood of further events impacting the world and so business are highly likely.

Resilience Defined

Resilience is defined as ‘the capacity to recover quickly from difficulties; toughness’. In the current and future global environment, it will be essential that the ‘supply chains’ are resistant and can recover quickly given the importance of identifying the right products and getting them to the consumer in the most cost effective and efficient manner.

In the context of global supply chains and the sourcing function, the key areas of focus in building this resilience should be:

- Partnerships – This should not be underestimated. We have mentioned this ad nauseam over the past couple of years, but long term relationships with suppliers, who share the same goals, will build in flexibility and allow for enhanced resilience through the ability to be creative with solutions as required.

- Supplier rationalisation – In line with the first point, a tighter network of supply partners will only help with volume, price points, and commercial opportunities.

- Market coverage – Having multiple sourcing jurisdictions where you have onboarded suppliers will negate any regional disruption. Ideally, there will be supplier partners who you can work with in multiple markets across the same product categories as long as volumes allow this. In addition, thinking through how you access these markets on the ground and manage your suppliers.

- Predictive Data – Building the capability to better predict, prepare and respond to changing needs. This should be encouraged by giving prominence to sourcing or buying at Board level.

- Sustainability – There is the ever pressing need to deliver sustainability commitments, which will also fall on the shoulders of the sourcing function. In this sense, resilience is seen in the context of viability and the ability of the suppliers to meet the company’s needs (and those of the consumer).

Summary

The World Economic Forum predicts that the World will have to deal with a range of challenges in their 2022 risk register. The signs are already there and commentators are pointing to the economic storm clouds building on the horizon.

For companies to recover and build a future of robust growth, greater emphasis and investment needs to be given to the role of the sourcing/buying function. As the role of Sourcing/Buying Director expands to become a central part of strategic planning and delivery, the old transactional approach to supply base management will have to be renewed. This needs to happen to build the resilience required form companies to perform over the medium term.

Whatever your needs, we are here help you source from global sourcing markets. Our solutions can help build the resilience that you need. For more information, please contact us at contact@et2cint.com