Global Trade Disruption Impacting Supply Chains

Global Trade Disruption Impacting Supply Chains Read More »

In the fast-paced environment of modern business world, one strategic tool emerges as a beacon of foresight—supply chain forecasting. Supply chain forecasting has a pivotal role where predicting demand, anticipating risks, and navigating volatile markets is harder than ever. In todays world of Global Sourcing and Procurement Supply chain forecasting uses a blend of art and science, intuition and data-driven insights, to guide procurement, production, and logistics decisions. But with ever-evolving consumer preferences, unpredictable disruptions, and geopolitical uncertainties, getting it right is no easy.

Supply chain forecasting is the strategic process of predicting future demand for products or services based on a combination of historical data, market analysis, and contextual factors. It acts as the compass guiding supply chain professionals, offering a glimpse into the future to inform decisions related to production, inventory, and distribution.

Technology is undoubtedly powerful, but human expertise remains a vital ingredient in supply chain forecasting. Interpretive judgment, understanding of market nuances, and agility in adapting to unforeseen circumstances are all crucial for extracting real value from data and algorithms.

ET2C International has for over twenty years played a crucial role connecting global brands and companies with sourcing partners. Our expertise in global sourcing and supply chain can make sure you get all the benefits of sourcing from China and Asia without any of the risks.

Our 250 colleagues are based in offices in seven key Asian sourcing markets to make your global sourcing simpler. Where language, time zone or business communication practices can make things difficult, our team will be your bridge to your suppliers.

Our team of experts can help you in making accurate supply chain forecasting. Giving you independent feet on the ground and confidence with fast responses, removing time zone and language challenges.

As technology and data analysis evolve, supply chain forecasting will become even more sophisticated and integrated. Expect real-time insights, hyper-connectivity, and predictive analytics to drive even more effective decision-making. Through embracing advanced technologies, cultivating collaboration, and adopting a mindset of continuous improvement, businesses can not only meet the challenges of today but also pioneer the future with confidence. Supply chain forecasting becomes the beacon illuminating the path to resilience, efficiency, and success in the ever-evolving landscape of commerce.

Join us in unraveling the art of supply chain forecasting—where foresight transforms challenges into opportunities, and businesses master tomorrow with confidence. Contact with us at If you would like to discuss how we can help you in your forecast, please contact@et2cint.com

Mastering Tomorrow: Unraveling the Art of Global Supply Chain Forecasting Read More »

The plan to near shore supply chains has been talked about since the pandemics first waves struck global supply chain networks fragmenting the previous structures and organisation. The immediate impact was a desire and corporate focus to develop shorter supply routes, rebuild partnerships and build more resilience by removing distance.

The immediate rush and to redevelop Global Sourcing Strategies, shorten supply routes and ‘Near Shore” is not being delivered. As the simple ideal of moving sourcing markets is proving much tougher to achieve than anticipated for Sourcing and Procurement teams.

The aftershocks to global trade and supply chains after the Pandemic have been many and unexpected regularly buffeting the smooth winds of commerce:

ET2C are a UK owned Global Sourcing company with over 22 years experience in making sourcing simpler for our clients. Our 200 colleagues are based in 7 major and emerging sourcing markets to ensure they can be your bridge to your supply chain partners. We work with clients from Early stage start-ups and challenger brands to global retailers to ensure their sourcing and procurement is as effective as possible. https://et2c.com

The background to the rush to Near or Friendly shoring has been the nearly five years of open economic conflict between the US and China. US-China trade flows hit an all-time record of $690.6 billion in 2022. Connecting the countries by a larger movement of trade than any other Nations (without shared borders).

Suggesting that Globalisation is not showing signs of halting. DHL in their recent report suggest that the US-China trade relationship is beginning to show a “general pattern” of decoupling even as globalization more broadly remains resilient, according to DHL’s global connectedness index.

“International flows have proven remarkably resilient through recent crises, and they strongly rebut the notion that globalization has given way to deglobalization,” according to the report, produced with New York University’s Stern School of Business.

“Today’s threats to globalization, nonetheless, are real and demand serious attention,” it continued. “It would be a mistake to infer from the recent resilience of international flows that globalization cannot go into reverse.” What has been the real world experience of brands and companies looking to Near Shore as part of their Sourcing Strategy ?

Brands are finding few factories outside the country that can produce the quality and quantity they require.

When Lanny Smith founded Actively Black Inc. in 2020, he hired factories in China to produce the brand’s athletic wear. But last year, concerned about production delays caused by China’s Covid lockdowns, Smith explored buying elsewhere. He shipped samples to a supply chain agent who’d assured him there were alternatives in Latin America. “He hit me back the next day and said, ‘You’re not going to find anybody who can do this in the Western Hemisphere,’” says Smith, 38, a former basketball star at the University of Houston.

For many companies buying from China has become more challenging in recent years because of increased tariffs, snarled supply chains, factory shutdowns under Beijing’s Covid Zero policy and rising geopolitical tensions. Factors which have combined to make

many Companies and brand owners investigate changing their Sourcing Strategy to be China +1 or to seek to replace China completely. Whilst on the face of it the idea has a lot of merit and upside finding suppliers who can match China for quality and price is not so simple.

Quitting China as a sourcing partner isn’t easy, and most progress has been concentrated in industries such as semiconductors that are considered vital to national security or have high added value. Producers of lower- tech, lower-margin and less added value products such as clothing, shoes, housewares and luggage are finding that few factories outside China have the machinery or the skilled workforce to deliver the quality and specifications required.

Since the 1990s, China has spent hundreds of billions of dollars transforming itself into the world’s premier location for manufacturing. Its factories have the machinery and expertise needed to produce quality products at a volume and pace that’s difficult to match. Along the 80-mile stretch from Shenzhen to Guangzhou, companies can weave, dye, sew, trim, label and package anything from T-shirts to tuxedos. And China’s investment in highways, railroads, air hubs and seaports has created a smooth path from factory gate to consumers worldwide.

Twenty years of Global Trading growth between China and the World is not something that can be dismantled quickly and easily. China’s advantages as a sourcing destination are so great that many companies that have tried to move away have returned at least a

portion of their production there. Even moving away from the Chinese mainland cannot guarantee moving away from China. As China has expanded its influence, support for infrastructure and factory investment to other countries such as Ethiopia.

When companies move manufacturing out of China, they often end up working with Chinese- owned suppliers or sourcing components and materials from the country.

Sourcing strategies are not always quick and easy to implement, the initial idea to relocate manufacturing from China to other Asian or African markets can suggest instant benefits. China’s experience of supplying and shipping products around the World is difficult to replicate. For some markets this may well require more product side compromises to deliver the geographic move.

ET2C Is a global sourcing company with over twenty years’ experience working with our clients to deliver their sourcing strategies. Our offices in seven countries ensure you always have a team on the ground to be your bridge to your Off Shore suppliers.

If you would like to explore Sourcing Strategy options or opportunities within China or in addition to China or to discuss your future challenges.

Please contact us at contact@et2cint.com

Is Nearshoring the Answer to Disrupted Supply Chains? Read More »

Global Sourcing 2.0 will define the response of Procurement and Sourcing Teams to another year of volatility in global trade. The range of impacts to the smooth running of global trade continue to build. Inflationary pressures continue to impact margin growth and the business need for Environmental and Supply Chain Risk management gains momentum. The risk of a protracted trade war using tariffs as the weapon of choice starts to loom large as elections take place in many countries. Most importantly the US presidential race which has already initiated companies’ scenario planning for a very different trade environment. The ongoing conflict in Ukraine and the Middle East are continuing to create huge challenges for Sourcing and Procurement Teams.

Procurement and Sourcing Team leaders who had hoped that economic conditions in 2024 would make their jobs easier than last year are already disappointed. As the new year began, the volatility and inflation of the previous year showed no signs of abating.

Many of the dimensions of change impacting business in 2023 are likely to still be with us in some form at the outturn of the year. Procurement and Sourcing functions are responding to these wide-ranging challenges in an equally wide range of structural changes and ways of working adaptations. Sourcing teams are facing the New Challenge of Global Sourcing 2.0

ET2C International are a UK owned leading Global Sourcing Company. Over twenty two years trading history playing a crucial role connecting global brands and companies with sourcing partners, delivering Strategic Sourcing projects and working with clients on our unique buying office delivery model.

Our 250 colleagues are based in offices in seven key Asian sourcing markets (developed and emerging markets) with the sole mission to make your global sourcing simpler. Where language, time zone or business communication practices can make things difficult, our team will be your bridge to your suppliers.

At ET2C our history of delivering the benefits of global sourcing to our clients enables businesses to quickly and easily connect with factory partners who can deliver your product requirements, quality and compliance requirements and margin improvements.

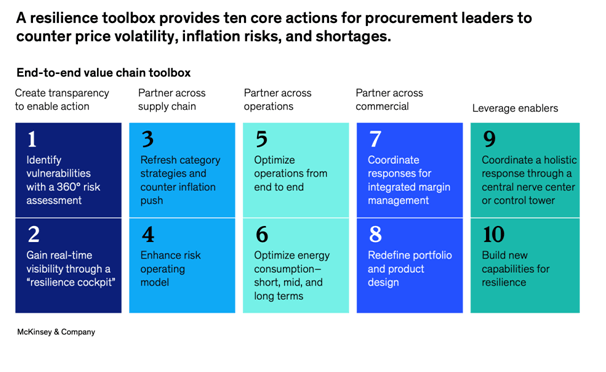

Understandably, the aggregate effect of these challenges has overwhelmed many procurement functions. Procurement can play a critical role in solving today’s most pressing business problems, but it cannot do so on its own. Winning now requires an entirely new level of resilience improvement and value creation built through a coordinated enterprise-wide effort.

Sourcing and Procurement is increasingly delivering a wider remit in business.

-Protecting against Corporate margin erosion

-Deliver on Environmental and Social Risk in Supply Chain

-Build Resilience against the next Black Swan event

Accordingly, success in protecting margins, containing cost escalation, and dynamically capturing opportunities requires an expanded mission for the procurement function. CEOs should consider positioning their procurement leaders at the center of the company’s response to the current context, tasked with a clear mandate to protect margins. CPOs can then mobilize executives for cross-functional impact and escalate investments in the talent and systems required to achieve and sustain outperformance.

Procurement leaders can combat volatility, inflation, and shortages and build resilience by taking ten core actions. The first critical element required is to gain transparency over the pressures and change drivers in their supply chain. Only be creating true visibility can they start to identify the key decisions required to deliver high level objectives. This will require support from all functions across the business and external partners to support Procurement in developing a more agile approach.

Risk Assessment of Supplier Network and Wider Value Chain

Risk Assessment of Supplier Network and Wider Value Chain As Procurement leaders wrestle with the new challenges of Global Sourcing 2.0 the need for a new range of additional skills becomes a critical need for effective delivery.

As Sourcing and Procurement teams play a more central role in business delivering their expanded contribution. The need to rapidly build skills will become a critical enabler to deliver their New Mission.

Global Sourcing 2.0 represents a shift in priority and ways of working. From the old Procurement model of expecting Suppliers to make and supply to a forecast and at the cheapest possible price.

To one where there is a more collaborative approach to Sourcing Strategy based on visible shared data, shared Environmental and Social

commitments and strong partnership for growth. A shared vision of the future that can inform the future requirements.

We have long argued that an approach based on strong partnerships is a more successful Sourcing model than the focus on Cost and make to Forecast.

As more companies move to re structure the deliverables of the Sourcing & Procurement team mission. Core competencies and skill sets need to be created, adopted and utilised.

Sourcing teams will need to rapidly build or bring in the skills required to bring full risk and impact visibility to their supply chain.

ET2C are a leading global sourcing company, with over twenty years’ experience supporting our clients to develop and deliver their sourcing strategies. We have seen a big rise in our clients demands for

-Strategic Sourcing Projects and Research

-Emissions measurement and management

-Risk identification

-Quality and Compliance. Social & ethical Auditing

As many companies move rapidly towards a future defined by Global Sourcing 2.0. Drop us a line to see how we could support you in your challenges

Email us at Contact@et2cint.com.

Navigating Global Sourcing 2.0: Challenges and Strategies for Procurement Teams Read More »

Global Sourcing 2.0 will define the response of Procurement and Sourcing Teams to another year of volatility in global trade. The range of impacts to the smooth running of global trade continue to build. Inflationary pressures continue to impact margin growth and the business need for Environmental and Supply Chain Risk management gains momentum. The risk of a protracted trade war using tariffs as the weapon of choice starts to loom large as elections take place in many countries. Most importantly the US presidential race which has already initiated companies’ scenario planning for a very different trade environment. The ongoing conflict in Ukraine and the Middle East are continuing to create huge challenges for Sourcing and Procurement Teams.

Procurement and Sourcing Team leaders who had hoped that economic conditions in 2024 would make their jobs easier than last year are already disappointed. As the new year began, the volatility and inflation of the previous year showed no signs of abating.

Many of the dimensions of change impacting business in 2023 are likely to still be with us in some form at the outturn of the year. Procurement and Sourcing functions are responding to these wide-ranging challenges in an equally wide range of structural changes and ways of working adaptations. Sourcing teams are facing the New Challenge of Global Sourcing 2.0

ET2C International are a UK owned leading Global Sourcing Company. Over twenty two years trading history playing a crucial role connecting global brands and companies with sourcing partners, delivering Strategic Sourcing projects and working with clients on our unique buying office delivery model.

Our 250 colleagues are based in offices in seven key Asian sourcing markets (developed and emerging markets) with the sole mission to make your global sourcing simpler. Where language, time zone or business communication practices can make things difficult, our team will be your bridge to your suppliers.

At ET2C our history of delivering the benefits of global sourcing to our clients enables businesses to quickly and easily connect with factory partners who can deliver your product requirements, quality and compliance requirements and margin improvements.

…

Navigating Global Sourcing 2.0: Challenges and Strategies for Procurement TeamsRead More »

Navigating Global Sourcing 2.0: Challenges and Strategies for Procurement Teams Read More »

The rise of strategic sourcing has significantly impacted the die casting industry and the market is undergoing significant evolution to align with the emerging demands of Strategic Sourcing plans. As companies seek to optimize their supply chains, die casters are evolving to meet these new demands. Die casting is facing many of the challenges to ways of working that many compaines face. As Sustainable and Circular business principals are adopted and commitments made by Sourcing compaines for their Global Sourcing plans.

Finding the right Supply partners has never been so important to ensure that Quality and Service is delivered with clarity on the Environmental and Social impact of the manufacturing process.

Die casting is evolving rapidly through investment in new prcess, sustainable design, material use and process efficiency. The Die casting market is etimated at $82b in 2024 and is expected to reach $112b by 2029 growing at a CAGR of 6.24Source: Mordor Intelligence Die Casting

China has become the market leader in innovative Die Casting with huge investemnt in innovation nad factory capacity. China is the first stop for global sourcing and procurement teasm in their search for high quality innovtive die casting.

ET2C are a UK owned Global Sourcing company who have ben trading for over 22 years. Our 200 colleagues strive each day to deliver our Mission to Make Sourcing Simple Safe and Fast for our clients.

Based in 7 offices across the globe in developed and emerging markets we work with clients to create and deliver effective sourcing strategies. Our industrial clients value our work across a range of process’s including Die Casting.

Our team will give you feet on the ground and become your bridget to Asian Supply partners. Ensuring you have peace of mind and deep partnership for growth. If you would like to know more drop us a line at contact@et2cint.com

Die casting remains a vital process for many industries. It offers several advantages, including:

The growing demand for die cast components is shaping the industry in several key areas:

Customization, Speed, and Sustainability in Die Casting

Modern sourcing demands are also influencing die casting:

Strategic sourcing helps companies ensure their global procurement effectively delivers:

For over 21 years, ET2C has helped industrial clients build and execute their global sourcing strategies. We act as a bridge to strategic sourcing partners in Asia, ensuring complete supply chain transparency and meeting all quality and compliance standards. We simplify sourcing by providing you with a team “on the ground” across seven countries, ensuring your sourcing plans are delivered effectively.

Contact us at contact@et2cint.com to learn how our experience can help you build a winning global sourcing strategy and gain a competitive edge.

Die Casting: Global Sourcing of Die Cast Components Read More »

As businesses navigate the ever-evolving terrain of global supply chains and commerce, mastering the intricacies of sourcing and procurement has become paramount. But amidst the buzzwords and industry jargon, it’s crucial to grasp the fundamental disparities between these essential functions. How can we decode the intricacies of sourcing and procurement, unravelling their distinct roles and uncovering the transformative potential they hold for businesses across industries.”

Interchangeable words or unique, complementary activities that together can unlock superior business performance ?

Sourcing and procurement are two related but distinct activities that are essential components of an overarching strategic supply chain management plan.

While sourcing and procurement are distinct activities, they are closely related and often overlap in practice. A strategic sourcing approach can help companies optimize their procurement activities by ensuring that they are working with the best suppliers and getting the best possible prices and terms. Procurement, in turn, is an important part of the sourcing process, as it involves executing contracts and managing supplier relationships to ensure that goods and services are delivered on time, at the right quality, and at the agreed-upon price.

Building a strong Sourcing Strategy and Executing the resultant Procurement Strategy can deliver a range of benefits

…

Strategic Sourcing and Procurement: Essential Strategies for Business SuccessRead More »

Strategic Sourcing and Procurement: Essential Strategies for Business Success Read More »

Vietnam is on a transformative journey as its manufacturing landscape and eco system builds creating a formidable player in global machinery sourcing. Uncover the key drivers behind Vietnam’s appeal as a sourcing destination, including cost advantages, industrial expertise, and favourable trade agreements.

Traditionally known for agricultural exports, the country has transformed into a competitive force in manufacturing, particularly machinery, equipment and engineered components.

Vietnam, nestled in Southeast Asia, has undergone remarkable economic transformation over the past few decades. Vietnam’s economic transformation began with bold reforms in the late 1980s. Embracing a market-oriented approach, the country opened its doors to foreign investment, fostering the growth of export-driven industries like textiles, electronics, and machinery. Today, Vietnam boasts a dynamic workforce, favourable investment policies, and a thriving manufacturing sector.

ET2C have been helping clients to make their sourcing simple for over 22 years. Our 200 colleagues are based in seven key Asian sourcing markets, including Vietnam, to ensure you always have feet on the ground. Our team become your bridge to your sourcing partners which can be vital where time zones, language and business communication standards maybe different.

We develop and implement global sourcing strategies delivering as range of benefits to our clients:

To see how we could support your sourcing and procurement needs please message us at contact@et2cint.com

Several factors make Vietnam a compelling choice for sourcing machinery. Making it a country that every sourcing and procurement professionsal should consider as part of tehir global sourcing strategy.

Cost Advantage : With relatively low labour costs compared to its neighbours, Vietnam offers competitive manufacturing costs, making it an attractive destination for machinery sourcing.

Proven Expertise: The country has developed a strong track record in manufacturing machinery and related components, particularly in industries like electronics, textiles, and machinery.

Favourable Trade Agreements : Vietnam’s participation in free trade agreements, including the WTO, CPTPP, and EVFTA, enhances its competitiveness and reduces trade barriers, making it easier for businesses to source machinery from the country.

Industrial Infrastructure: Significant investments in industrial and transportation infrastructure, including industrial parks, airports, and ports, have bolstered Vietnam’s logistics and supply chain capabilities, facilitating smoother import and export processes.

Supportive Government Policies: The Vietnamese government’s initiatives to promote foreign investment and export-oriented industries, coupled with a favourable business environment, further incentivize machinery manufacturers and exporters to operate in Vietnam.

Growth and Opportunities

Standard Chartered paints a rosy picture with a projected GDP growth of 6.7%, gradually accelerating throughout the year. Their forecast hinges on a strong second half, with growth economic growth reaching 6.9%

Challenges to Consider

While Vietnam offers immense potential, navigating the landscape comes with its own set of challenges. Language barriers, cultural differences, intellectual property concerns, and supply chain transparency require careful planning and mitigation strategies.

ET2C International, a leading global sourcing company with over 20 years of experience, can help you navigate these challenges. Our team of experts, strategically located in Vietnam, bridges the gap between you and your ideal Vietnamese factory partners. We handle communication hurdles, time zone differences, and quality control concerns, ensuring a smooth and successful sourcing experience.

Vietnam’s emergence as a strategic sourcing destination for machinery and equipment underscores its economic vibrancy and potential for growth. With its competitive pricing, manufacturing expertise, favourable trade agreements, and supportive government policies, Vietnam offers unparalleled opportunities for businesses seeking to diversify their supply chains and tap into Asia’s thriving manufacturing ecosystem.

To explore sourcing opportunities in Vietnam or discuss your future supply chain challenges, reach out to ET2C International at contact@et2cint.com

Explore the untapped potential of Bangladesh as a strategic sourcing hub. With its strategic location on global shipping routes and a burgeoning economy, Bangladesh offers compelling opportunities for businesses worldwide. Uncover the key factors driving its growth trajectory and how to leverage them effectively in your sourcing strategy.

Bangladesh is an emerging economy with a large and increasingly skilled workforce. Government infrastructure investments are building on its strategically strong position on Global Shipping routes to drive their Economic strategy. Making it a good choice for any strategic sourcing strategy to investigate.

Bangladesh is a country in South Asia. Bordered by India to the west, north, and east, and by Myanmar to the southeast. The Bay of Bengal lies to the south. Bangladesh was formerly known as East Bengal and was part of British India until 1947. A population of over 150miliion makes it the most densely populated country in the World.

The strategic location has been a huge benefit and driver of economic growth and foreign investment in the country with the USA, Japan and China all major investors.

Proximity to India and Myanmar gives easy access to over 1.5b consumers and the Bay of Bengal coastline supports access to major shipping routes.

Bangladesh is emerging as a dynamic, fast-growing market. This growth is driven by a large domestic consumer market, a rapidly expanding middle and affluent class, and an impressive digital adoption rate. The country is now home to more than 2,500 startups, with about 200 more being added each year, focusing on a wide range of industries, from FinTech to E-Commerce. The traditional trading base of companies continues to thrive continuing to play an important role in domestic and global supply chains for textile, apparel and garments.

“The government is managing relatively well against the impact of external adversities and has embarked on the reform programs as precautionary measures,” said ADB. Country Director for Bangladesh Edimon

Bangladesh made a strong recovery from C-19 impact but is now suffering from a slowdown in trade from the Ukraine War, cost inflation and softening of demand in many markets. The implementation of a range of key initiatives in its economic strategy will foster economic growth and development in the medium term. manufacturing, and aquaculture .

The country’s economic strategy focuses on various structural reforms designed to make the country an easier and more accessible country to do business with and to reduce reliance on Garments and Apparel. Currently accounting for over 80% of exports from the country the dominance of these categories in export trade are recognised as a potential weakness/risk for the country

ET2C have been helping clients to make their sourcing simple for over 22 years. Our 200 colleagues are based in seven key Asian sourcing markets to ensure you always have feet on the ground. Our team become your bridge to your sourcing partners which can be vital where time zones, language and business communication standards maybe different.

We develop and implement global sourcing strategies delivering as range of benefits to our clients:

To see how we could support your sourcing and procurement needs please message us at contact@et2cint.com

The implementation of these seven strategic planks will make Bangladesh a more attractive country to trade with and a sourcing destination worthy of serious consideration in any sourcing strategy.

The government has identified deep water ports as a key priority for economic development. The country has two deep water ports: Chittagong and Mongla. Chittagong is the larger of the two ports, and it is the main gateway for international trade. Mongla is a newer port, and it is located in the south of the country.

The government is investing in expanding and upgrading both ports. The expansion of Chittagong port is expected to be completed by 2023. The expansion will include the construction of a new container terminal and a new oil terminal. The expansion of Mongla port is expected to be completed by 2025. The expansion will include the construction of a

new container terminal and a new coal terminal.

There is further investment in the construction of a new deep-water port in Sonadia. The Sonadia port is expected to be completed by 2030. The port will be located on the Bay of Bengal, and it will be able to handle large container ships and tankers.

The investment in deep water ports is expected to boost trade and economic growth in Bangladesh. The ports will provide a gateway for international trade, and they will also help to attract foreign investment. The ports are also expected to create jobs and boost economic development in the coastal regions of Bangladesh.

Investment and Business-friendly Policies: Bangladesh has implemented policies to attract domestic and foreign direct investment. These policies include providing tax incentives, simplifying procedures for business registration and licensing, ensuring investor protection, and establishing special economic zones (SEZs) to promote industrial development.

Government infrastructure investments are building on its strategically strong position on Global Shipping routes to drive their Economic strategy. Making it a good choice for any strategic sourcing strategy to investigate.

However, it’s important to note that sourcing from Bangladesh can also come with challenges. Language barriers, cultural differences, intellectual property protection, and ensuring supply chain transparency are factors that require careful consideration and management.

We are a leading Global Sourcing company with over twenty year’s experience working with our clients. Our team of 200 colleagues are based in seven offices in key sourcing markets across Asia.

We work with our clients to create and deliver their global sourcing strategies, becoming their bridge to their supply partners. Where time zones, language, business communication expectations or QC can become challenging.

Our team of experts can help you build and deliver your sourcing strategy and ensure you are working with the right factory partners. Giving you independent feet on the ground and confidence with fast responses, removing time zone and language challenges. If you would like to explore sourcing opportunities within Bangladesh or to discuss your future supply chain challenges. Please contact@et2cint.com