The development and deployment of Global Sourcing Strategies have supported the growth of Die Casting and the emerging demands and trends for Die Casting products.

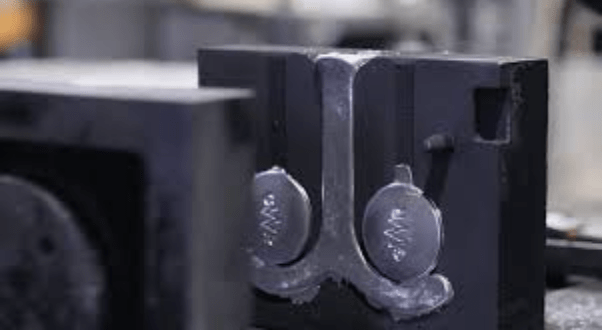

Die casting is a manufacturing process used to produce metal components by injecting molten metal into a reusable mould. The molten metal is forced under high pressure into the mould cavity, where it solidifies and takes the shape of the mould. Once the metal has cooled, the die is opened, and the solidified part, known as a casting, is ejected.

Die casting offers several advantages over other manufacturing processes, such as:

- High accuracy and dimensional consistency: Die casting can produce parts with tight tolerances and high dimensional accuracy.

- Rapid production: Die casting is a highly efficient process, allowing for the production of a large number of parts in a short time.

- Complex shapes and thin-walled sections: Die casting enables the production of complex geometries and intricate details that may be challenging or costly to achieve with other manufacturing processes.

- Material versatility: Die casting can be performed using a wide range of metals and alloys, including aluminium, zinc, magnesium, and copper.

- Cost-effective for large-scale production: Die casting can be cost-effective for large production runs due to its high production rate, minimal material waste, and reduced post-processing requirements.

How is the growing market for the Die cast products and components shaping the development of the process, material usage and sustainability?

- Lightweight and eco-friendly materials: With a growing focus on sustainability and energy efficiency, there is an increasing demand for lightweight components. Die casting can offer lightweight solutions by utilising materials like aluminium and magnesium alloys, which have excellent strength-to-weight ratios.

- Complex geometries and miniaturisation: As industries evolve, there is a need for more complex and miniaturized components. Die casting can provide intricate shapes and intricate details, allowing for the production of parts with complex geometries.

- Integration of automation and digital technologies: Automation and digitalization are transforming various manufacturing processes, including die casting. Advancements in robotics, artificial intelligence, and data analytics are enabling improved process control, quality assurance, and productivity.

- Customization and rapid prototyping: Clients are increasingly demanding customized components and faster product development cycles. Die casting offers the flexibility to produce complex shapes and customize designs while maintaining production efficiency.

- Sustainability and Recycling: As sustainability becomes a priority, the die casting industry is likely to focus more on recyclability and waste reduction. Efforts may be made to improve material efficiency, optimize energy consumption, and implement closed-loop systems for material recycling.

Summary

Die Casting is becoming an increasingly important process for many industries with its ability to light weight highly technical and complex shapes and designs. It has the capability to deliver high quality, complex designs with a good cost base. Delivered with a high degree of supply chain sustainability and transparency.

Global Sourcing Strategies are the critical starting point for companies to ensure their global procurement is effectively delivering:

- Product quality

- Sustainability

- Speed of manufacturing

- Communication

- Quality and Compliance

- Cost and Supply

At ET2C we have been working with our Industrial clients to build and delivery their Global Sourcing Strategies for over 21 years. Working to become our clients bridge to their Strategic Sourcing partners in Asia. Ensuring full transparency in their supply chain and all Quality and Compliance standards are met in full. Making Sourcing Simple

We have over 250 colleagues based in seven countries to give you feet on the ground to ensure your Sourcing plans are delivered effectively.

If you have any questions or would like to explore how you could benefit from our experience, please drop us a message at contact@et2cint.com and see how we could help you build your Global Sourcing Strategy and deliver increased competitive advantage.