Industrial Components

At ET2C, we specialize in sourcing precision engineered industrial components across a range of different manufacturing processes. Our Asian based team have the expertise needed to provide our clients with an upstream technical capability that delivers lower costs. Our long term relationships with trusted suppliers allow us to provide an unrivalled service to our clients.

What We Do

We help to identify the most suitable factories for your product needs and help you through the entire manufacturing process. For industrial components, we have own proven methodology that adds to our tried and tested sourcing process.

Proven Methodology

From the moment we receive our customer’s drawing or specification, our local teams analyse the requirements and assess the opportunities from across our supplier base taking into account specific sourcing market opportunities and advantages (such as tariffs or technical capabilities). In accordance with ISO 9001, we are committed to delivering high-quality products to our customers by implementing our Quality Assurance and Quality Control methodologies throughout the manufacturing process to greatly reduce the margin of error on tolerances. This is a consistent approach at any stage of the critical path, whether during the sampling phase for prototypes, mould inspections right through to production.

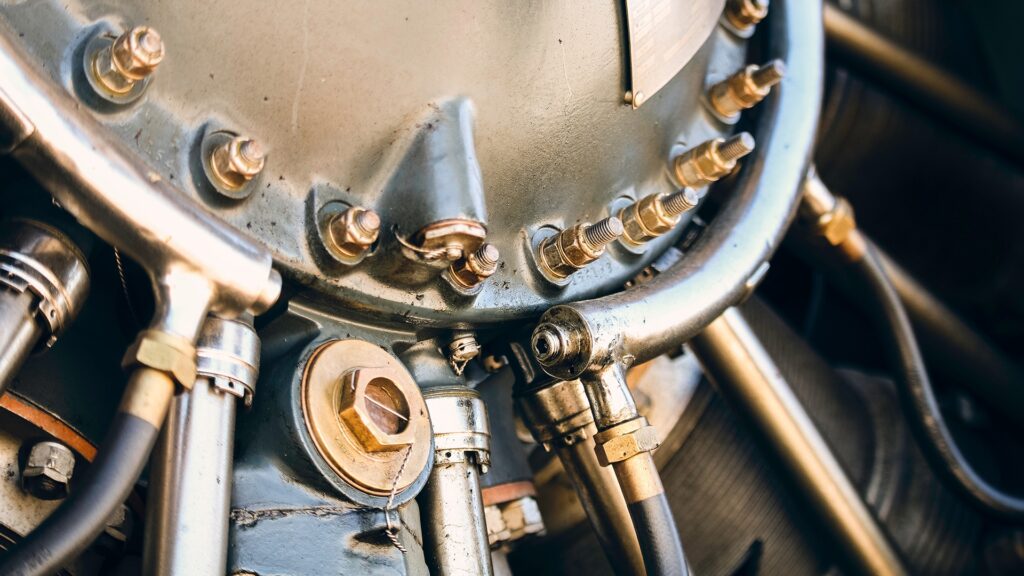

Metal Components

Various manufacturing methods and materials are available to suit a wide range of applications including transport, heavy equipment, household, hardware, electrical equipment, machines and machine tools.

Forging

We have reliable forging suppliers across China, India and Vietnam and are aware of the benefits of forging for sustainability, with raw waste being dramatically reduced. Materials available include Aluminum, Steel and Brass. Good for better mechanical properties, metal structure refining, elimination of porosity and minimum weight.

Casting

Across our supplier base, we have range of capability from high pressure, to sand and gravity casting. Materials available include Aluminum Alloy, Zamak, Iron, Brass, Stainless Steel. Good for low tooling cost, dimensional consistency, rapid production rates, good surface finish and close tolerance.

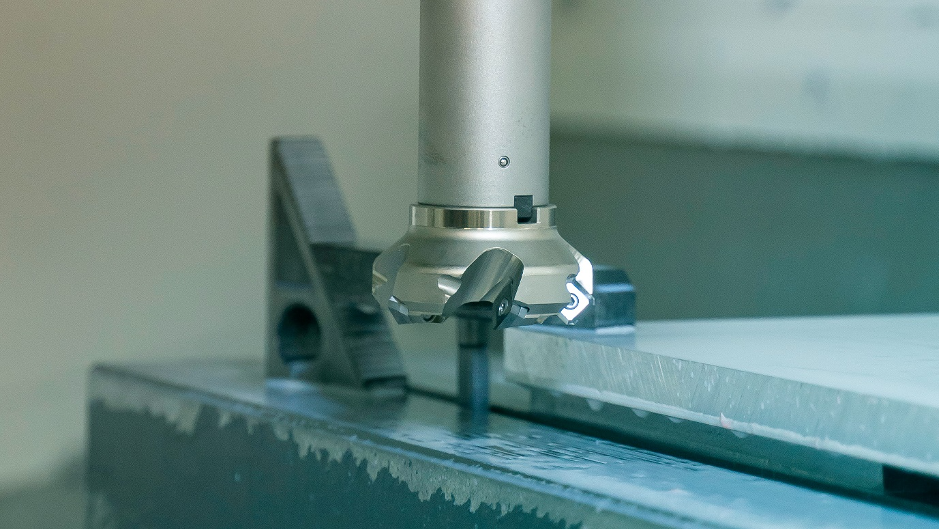

CNC Machining

We work with our suppliers to provide bespoke parts for our customers predominately from our Chinese supplier base. Good for high accuracy, smooth surface finishes, special geometric features and a variety of work materials.

Sheet Metal Fabrication

We have reliable suppliers to produce custom-made products that are manufactured using a range of stamping methods such as embossing, bending, flanging, blanking, ironing, drawing, stretching, hemming, curling, cutting and piercing.

Extrusions

Aluminium extrusion is one of the most popular forms of aluminium products used every day in a number of innovative application areas. They are used for their strength, flexibility, durability and sustainability in a number of end user sectors such as construction, transportation, electrical, machinery and consumer durables.

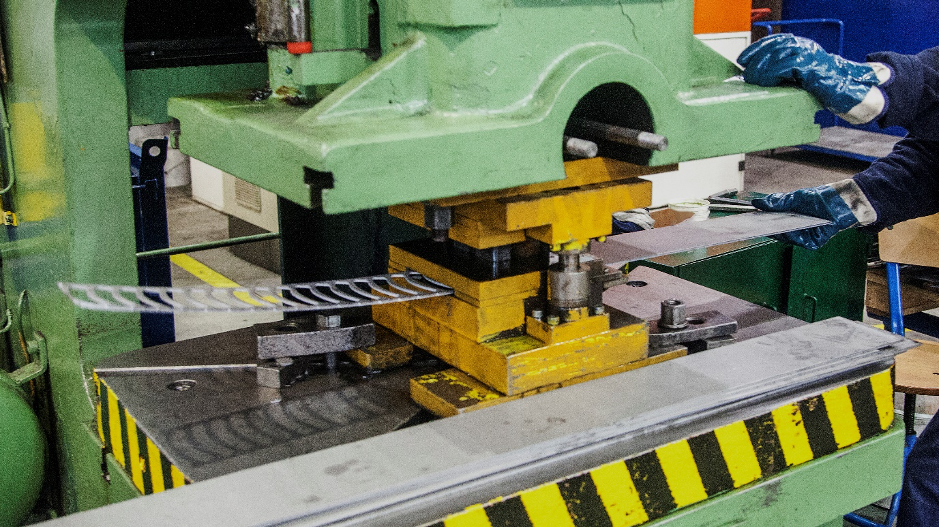

Stampings & Pressings

We specialise in metal pressings using a variety of ferrous and nonferrous metals like Aluminium, Stainless Steel, Copper, Brass and Mild Steel. Stampings have been used in numerous markets, including aerospace, automotive, domestic electrical power generation and regeneration.

Request a Quote

If you’d like to find out how we can help your business thrive, contact us today for a free quotation.

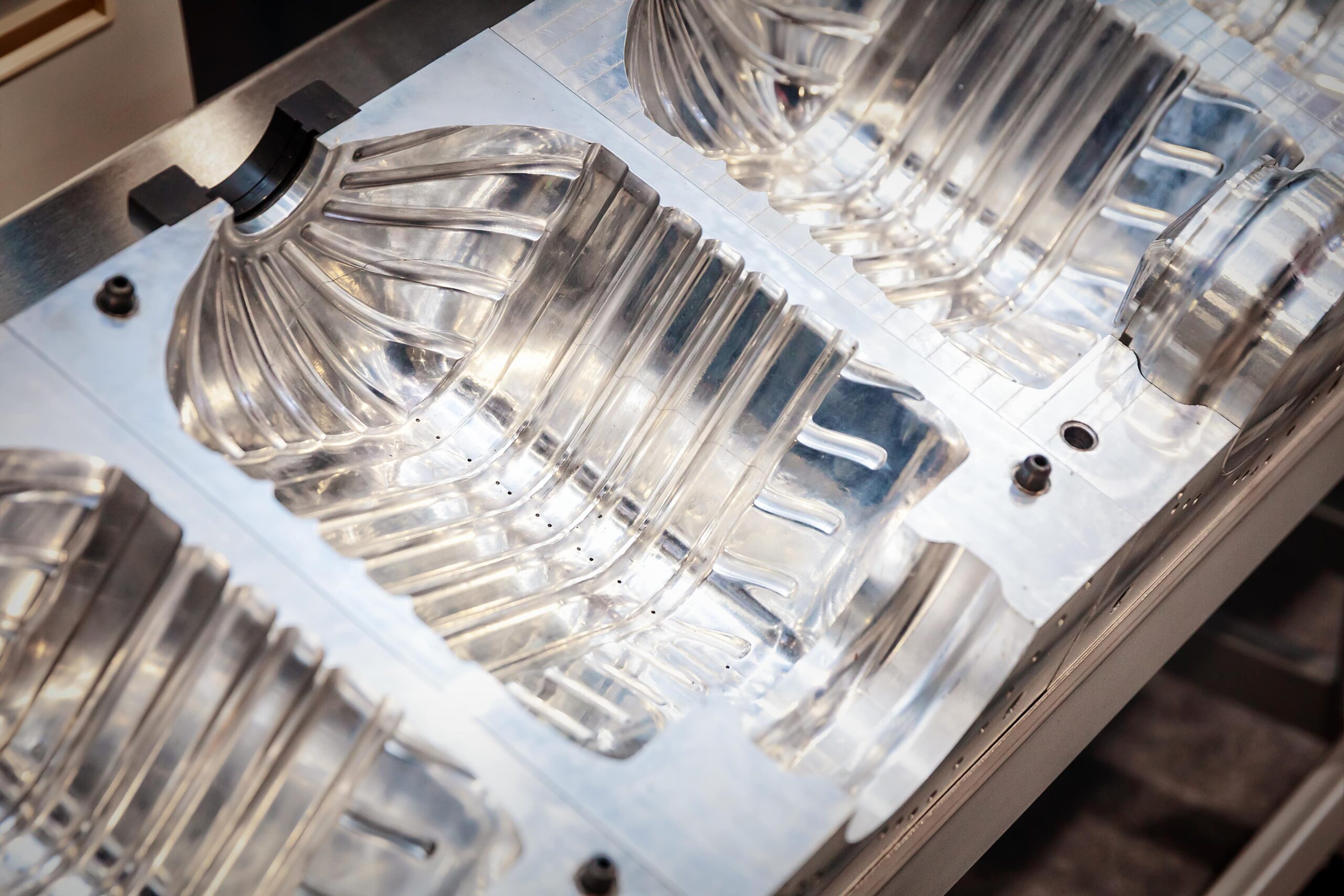

Plastic Components

We work with a number of high quality plastic injection moulding suppliers to manufacture complex components in different shapes, designs and weights, with high production output and ability to insert mould and overmoulding.

Achieve the right balance

ET2C can help you achieve the right balance between price, quality and delivery. We work hard to the outset to ensure we understand the details and to deliver against the brief. Let us help you successfully navigate the obstacles of manufacturing in a foreign country, while minimizing the necessary efforts.