Die casting has experienced significant growth as a manufacturing process, driven by several factors including technological advancements and the expansion of global sourcing from production facilities in Asia.

The Asia-Pacific region has emerged as the largest and most dynamic die casting market globally, accounting for nearly half of global market demand.

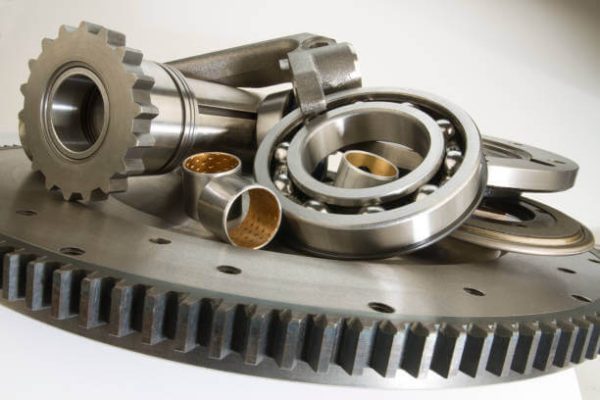

Die casting, a cornerstone of modern manufacturing, continues to be a vital process across diverse industries. Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity :

From automotive and aerospace to consumer electronics and industrial machinery, die-cast components play a crucial role in manufacturing. However, the landscape of global sourcing is rapidly evolving, presenting both challenges and opportunities for the die casting industry. This article explores the future of die casting in this dynamic environment of global sourcing, examining key trends, the importance of strategic sourcing, and how companies can leverage global partnerships to achieve a competitive edge.

The Evolving Landscape of Die Casting in Global Sourcing:

The die casting industry is not static. It’s constantly adapting to meet the changing demands of modern supply chains. Several key trends are shaping its future:

Lightweighting: Driven by fuel efficiency in transportation and material conservation in other sectors, the demand for lightweight components is increasing. Die casting, particularly with aluminum and magnesium alloys, offers excellent potential for lightweighting without sacrificing strength or performance. For further insights please read :

Advanced Materials: Research and development into new die casting alloys, including high-strength aluminum, magnesium, and even metal matrix composites, are expanding the possibilities for die-cast components. These materials offer enhanced properties like improved strength, corrosion resistance, and thermal conductivity.

Sustainability: Environmental concerns are pushing manufacturers to adopt more sustainable practices. This includes using recycled materials, minimizing waste, and reducing energy consumption in the die casting process. Life cycle assessments and eco-friendly die casting practices are becoming increasingly important.

Automation and Industry 4.0: The integration of automation, robotics, and data analytics (Industry 4.0) is transforming die casting operations. These technologies enable greater efficiency, precision, and quality control, while also reducing costs and lead times.

Complex Geometries: Die casting’s ability to produce complex shapes and thin-walled sections makes it ideal for manufacturing intricate components with tight tolerances. This capability is crucial for meeting the demands of increasingly sophisticated product designs in global sourcing world.

ET2C International Global Sourcing Experts

ET2C International have been working for over 23 years to Make Sourcing Simple for our clients. Our 200 colleagues are based in 7 offices in major sourcing markets.

Giving you a team on the ground to deliver your Strategic Sourcing ambitions and be your bridge to your Asian sourcing partners. ET2C International offer a range of service to Grow your Margin, Remove Risk and Deliver Simplicity. We offer our clients:

- Consultancy-Creating your Global Sourcing Strategy

- Sourcing & Procurement -Execution on the Ground

- Quality & Compliance – QA/QA ensuring Product Quality

- Buying Office Service-Unlocking the Value of Asian Sourcing

Die Casting Advantages for Global Sourcing

Die casting offers several compelling advantages that make it well-suited for global sourcing:

Cost-Effectiveness: For high-volume production, die casting can be highly cost-effective due to its high production rates, minimal material waste, and reduced post-processing requirements.

Design Flexibility: Die casting allows for the production of complex shapes and intricate details, offering designers a high degree of flexibility.

Material Versatility: A wide range of metals and alloys can be used in die casting, including aluminum, zinc, magnesium, and copper, catering to diverse applications.

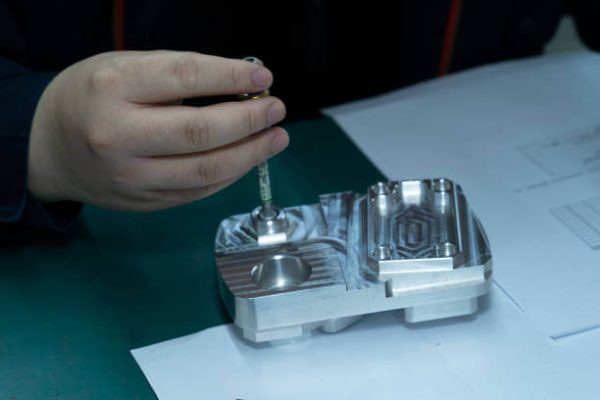

Dimensional Accuracy and Consistency: Die casting produces parts with tight tolerances and high dimensional accuracy, ensuring consistent quality.

Rapid Production: The die casting process is highly efficient, enabling rapid production and shorter lead times.

Sourcing Die Cast Components from Asia: A Strategic Approach for Global Sourcing

Asia has become a major hub for die casting manufacturing, offering a combination of competitive costs, skilled labor, and advanced manufacturing capabilities. However, sourcing from Asia requires a strategic approach. Companies need to carefully evaluate potential suppliers, considering factors like quality, capacity, lead times, and compliance with international standards.

In today’s interconnected world, global sourcing is no longer a choice but a necessity for many businesses. For the die casting industry, effective global sourcing strategies are essential for accessing the best resources, optimizing costs, and staying competitive. These strategies must go beyond simply finding the lowest price.

What to Consider When Determining an Optimal Global Sourcing Stragety

Supplier Capabilities: Identifying and vetting reliable suppliers with the necessary expertise, capacity, and quality control systems is paramount.

Quality Assurance: Maintaining consistent quality across a global supply chain requires robust quality control processes, including inspections, audits, and certifications.

Logistics and Supply Chain Management: Efficient logistics and supply chain management are crucial for ensuring timely delivery and minimizing disruptions.

Risk Management: Global sourcing introduces various risks, including political instability, natural disasters, and supply chain disruptions. Companies need to develop strategies to mitigate these risks.

Ethical and Sustainable Sourcing: Increasingly, companies are focusing on ethical and sustainable sourcing practices, ensuring fair labor practices, environmental responsibility, and social compliance throughout their supply chains.

ET2C International: Your Strategic Sourcing Partner in Die-Casting

Navigating the complexities of global sourcing can be challenging. Partnering with a reputable sourcing agent like ET2C International can provide significant advantages. With over 20 years of experience, ET2C specializes in global sourcing strategy and procurement. Our team of 200 colleagues operates in seven key sourcing markets, giving us on-the-ground expertise and a deep understanding of local market dynamics.

We act as a bridge between our clients and their supply partners in China, India, Vietnam and Turkiye. We overcome language barriers, time zone differences, and cultural nuances, simplifying the sourcing process and ensuring effective communication. Our expertise extends to identifying and vetting qualified factories, negotiating favorable terms, managing quality control, and overseeing logistics. Whether you are sourcing from China, India, Vietnam and Turkiye, ET2C can help you develop and implement a successful global sourcing strategy.

Conclusion

The future of die casting is bright, driven by innovation, advanced materials, and evolving market demands. However, success in this dynamic environment requires a strategic approach to global sourcing. By partnering with experienced sourcing agents like ET2C International, companies can navigate the complexities of global supply chains, access the best resources, and achieve a competitive advantage in the global die casting market. Contact us at contact@et2cint.com to learn how we can help you build your global sourcing strategy and unlock the full potential of die casting. For building effective die casting sourcing strategies, Contact us at contact@et2cint.com.

David Young

Position: Group Marketing Director

David Young is an experienced strategic sourcing commentator and thought leader with over 20 years of marketing and innovation experience. Connect with David on LinkedIn or david.y@et2c.com.